| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Type | Compact Band Filter |

| Certification | CE Certified, ISO 9001:2008 |

| Application | Grinding Lapping, Gun Drilling, Wire Drawing, Coolant Filtration |

| Click to view more | |

Product Details

We Shubh laxmi Machine Tools ( Cleanmake Products LLP ) Leading Manufactures and Exporter of Coolant Filtration System Since 1975 . We Shubh laxmi Made compact band filter is a revolutionary and pioneering development in band filter technology. The unique filter has no relative movement between the conveyor, filter paper, wheels and sludge drivers. Even large amounts of dirt and shavings cannot damage the filter paper. The system requires up to 80 per cent less space than a flat-band filter without any restrictions in terms of filtration output and, indeed, with greater cleaning efficiency.

Principle

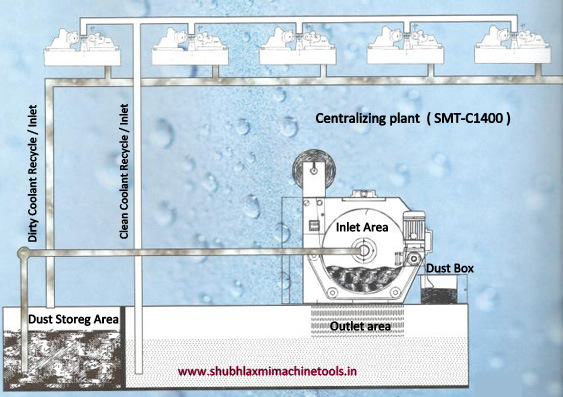

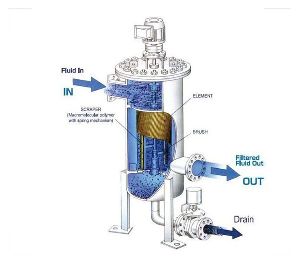

A continuous sturdy metal-jointed band conveyor is fitted to form a half-shell between two rotating disc wheels. The loop formed by the wheels is 180°.The conveyor is driven by a geared motor connected to a drive shaft. The filter paper is inserted between the tensioned conveyor and the wheels. The filtration tank is sealed on all sides.

The medium to be filtered is introduced into the tank through the central input pipe. By positioning the pipe centrally the medium to be filtered is brought directly from the machine into the filter unit, making a lift pump unnecessary. We Shubh laxmi Made compact band`s turbulent zone at the band inlet produces an arc-filter effect, which keeps the filter paper free of dirt and hence permeable at this point. The particles settle in the non-turbulent area of the filter reservoir to form a cake. The cake itself acts as an additional filter layer, thereby enhancing the filtration effect even further. A pool forms gradually as the particle deposits build up on the paper. Depending on the type of filter a level of up to 400 mm can be achieved. We Shubh laxmi Made compact band`s high hydrostatic pressure produced in this way helps to ensure that the filter paper is used with maximum efficiency.

Once the maximum adjustable level in the tank is reached, the geared motor switches on and feeds new filter paper without any interruption to the filtration process. The level in the tank sinks and the conveyor stops. At the same time the sludge and used filter paper are discharged on the other end of the tank. Individual sludge scrapers can be fitted between the wheels to handle larger volumes of sludge. These drivers remove all sludge and coarse chips without damaging the filter paper. We Shubh laxmi Made compact band`s entire filtration process runs full automatically. The diameter of the paper roll is monitored by a special sensor and a signal is given when the paper is low. Various grades of papers are available to achieve the desired filtration effect.

Application

- Machine Tools Manufacturers.

- Textile Spindles Manufacturers.

- All Type Grinding Machine Manufacturers..

- Steel Bright Bars Division.

- Deep Hole Drill Machine Manufacturers.

- Chanterelles Grinding Machine Division.

- Water Treatment Plant.

- Gear Grinding Division.

- Tool Room Division.

- Bearing Manufacturers.

- Industrial Washing Machine Manufacturers.

- Steel Ball Manufacturers.

- Drill Manufacturers.

- Machining Industries.

- Roller Manufacturers Division.

- Tube Mill.

Benefits

- Product Quality Improve.

- Grinding Wheel Life Improve.

- Coolant Oil Life Improve

- Productive Improve

- R.A. Value Maintain